Our client, a mid-sized manufacturing company, produces automotive parts. The company has been in

operation for over 35 years but had been facing several challenges recently, including declining

profitability and a lack of a clear growth strategy. The client reached out to us to help to identify issues

and offer a goto market strategy

Engagement Overview

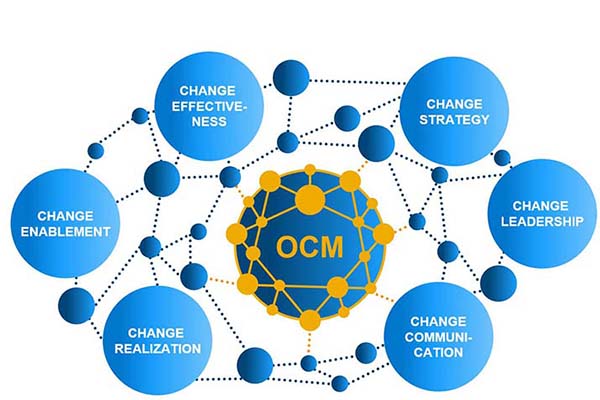

The primary objective was to improve business efficiency, identify cost-saving opportunities, and

develop a growth strategy.

Key Findings and Recommendations

Intent Point conducted a thorough analysis of the client's products, technologies, processes, team

capabilities, inventory management, financials, marketing strategy, and market position.

Operational Efficiency: Our team identified the bottlenecks and recommended implementing lean

manufacturing principles, streamlining workflows, and optimizing the supply chain to reduce costs and

improve productivity.

Operational Efficiency

10%

Cost Reduction

15%

Sales Growth

15%

Cost Reduction: We analyzed the client's cost structure, systems and identified areas of unnecessary

expenses. Our team suggested tools to get digitized and introduced effective technology solutions to

reduce procurement cost and manage excess inventory tracking with fair distribution of parts.

Cost Reduction: We analyzed the client's cost structure, systems and identified areas of unnecessary

expenses. Our team suggested tools to get digitized and introduced effective technology solutions to

reduce procurement cost and manage excess inventory tracking with fair distribution of parts.

Growth Strategy: Intent Point facilitated strategic planning sessions with the client's management team

to identify growth opportunities. They conducted market research, competitor analysis, and customer

surveys to understand market trends and customer preferences. Based on the findings, our team

recommended diversifying product offerings, exploring new markets, and investing in research and

development to stay ahead of industry trends.

Intent Point also offered new unexplored markets where products with minimum features can be sold at

mass.

Results and Impact

After implementing the recommendations, the client experienced significant improvements in their

operations and profitability.

Key outcomes

Cost Savings: The client was able to achieve cost savings of 15% through supply chain optimization and

streamlined procurement processes with fair inventory management.

Operational Efficiency: The implementation of lean manufacturing principles and process improvements

resulted in a 20% increase in overall productivity and a reduction in lead times.

Growth Initiatives: The client successfully diversified its product offerings, entered new markets, and

established strategic partnerships. These initiatives led to a 20% increase in revenue and improved

market positioning.